Expert Techniques for Preventing Weld Undercut Effectively

Expert Techniques for Preventing Weld Undercut Effectively

Blog Article

A Comprehensive Overview to Identifying, Fighting, and Repairing Undercut Welding Problems in Your Welding Jobs

In the realm of welding, experiencing undercut issues is a typical obstacle that can compromise the structural honesty and general quality of your welding projects. Comprehending the source behind undercut welding, having the ability to properly find it in your welds, and carrying out efficient preventative steps are essential skills for any type of welder. In addition, having the knowledge and strategies to rectify undercut issues when they do take place can make a significant distinction in the final result of your welding undertakings. Stay tuned as we check out the crucial parts of determining, stopping, and repairing undercut welding troubles, supplying you with beneficial understandings and techniques to boost your welding skills to the next degree.

Typical Reasons For Undercut Welding

Undercut welding, a common issue in welding processes, can be created by numerous variables that require to be carefully determined and resolved to ensure the honesty of the weld joint. One of the key causes of undercut welding is extreme warm input.

Another common reason for undercut welding is inappropriate welding strategy. Inadequate manipulation of the soldering iron or gun, incorrect angle or distance between the work surface and the torch, or irregular traveling speed can all add to the development of undercut. In addition, making use of the incorrect welding consumables or electrode dimension for a certain joint setup can cause undercut issues. Identifying these source and implementing rehabilitative procedures is necessary in stopping and fixing undercut welding problems in welding tasks.

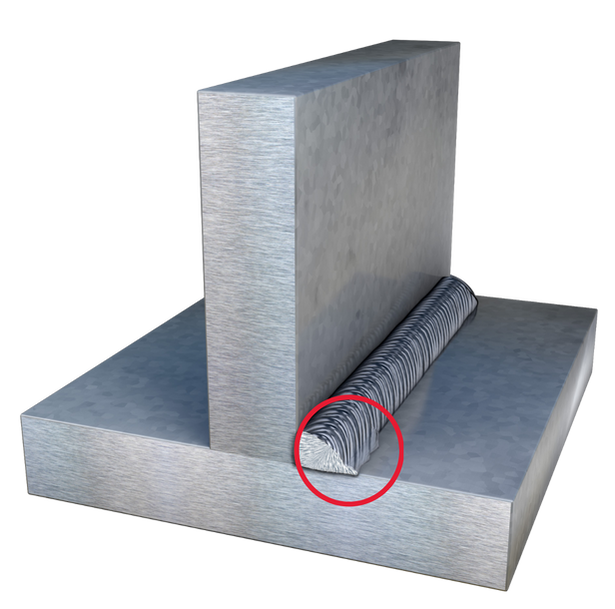

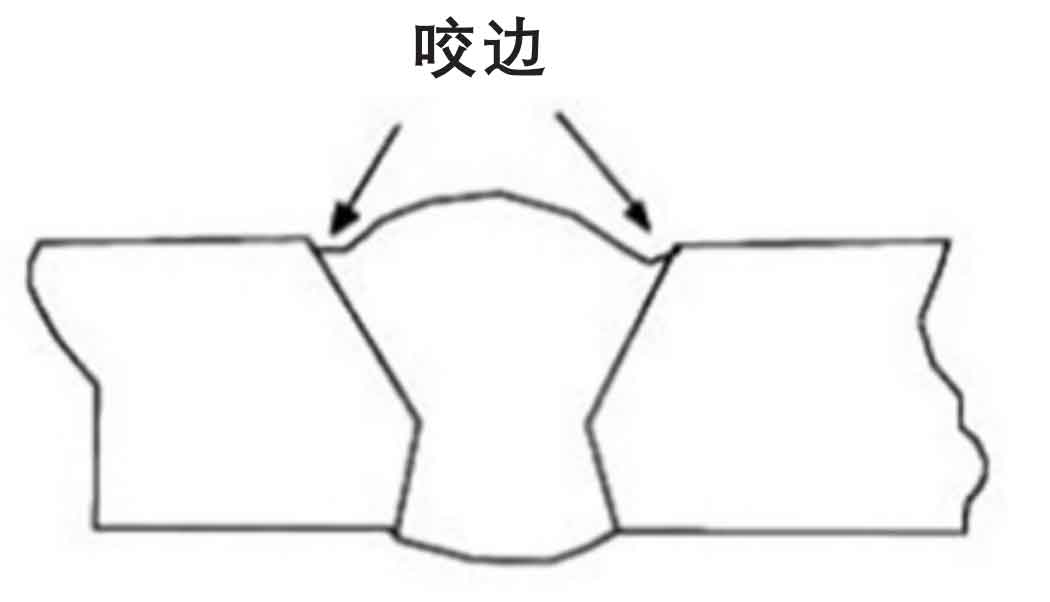

Identifying Undercut in Welds

To recognize undercut properly, correct lights and magnification tools are vital to check the weld joint thoroughly. Making use of tools such as a welding gauge or a magnifying glass can help in identifying even the smallest undercut blemishes. In addition, running a finger or a finger nail along the weld joint can in some cases disclose undercut, as the surface area might really feel unequal or have a dip where the undercut exists.

Preventive Measures for Undercut

Having a deep understanding of the causes of undercut in welds enables for the application of efficient precautionary measures to preserve weld quality and stability. These setups ought to be maximized to stop extreme heat input, which can lead to damage development.

Strategies for Fixing Undercut

Enhancing the welding existing find more information or reducing the traveling speed can help fill in the undercut. Additionally, transforming the welding method from a press to a drag or vice versa can likewise aid lessen undercut.

An additional technique is to use a weaving motion while welding to make sure correct sidewall blend and fill in the undercut. By oscillating the welding arc from side to side within the weld joint, the welder can deposit a lot more filler product right into the undercut locations, efficiently getting rid of the issue.

In addition, grinding out the undercut and rewelding the joint can be a feasible solution for more severe undercut problems - Preventing weblink weld undercut. This process entails removing the undercut area, preparing the base steel, and after that rewelding the joint with correct welding criteria and methods to prevent undercut from repeating

Expert Tips for Avoiding Undercut

Utilizing proper welding methods and preserving control over crucial welding parameters are essential methods for welders intending to stop undercut in their weld joints. In addition, selecting the suitable welding process and filler metal for the specific application can assist protect against undercut. Maintaining a regular travel rate throughout the welding procedure is an additional important idea to prevent undercut.

Final Thought

Finally, determining, protecting against, and fixing undercut welding issues in your welding jobs is critical for making sure strong and long lasting welds. Preventing weld undercut. By comprehending the usual sources of undercut, having the ability to determine it in welds, applying safety nets, and utilizing appropriate strategies for fixing undercut, you can stay clear of potential issues and develop high-quality welds. Following expert pointers for preventing undercut can assist you improve your welding skills and create much better lead to your tasks

Undercut welding, a typical issue in welding procedures, can be created by various aspects that need to be carefully determined and resolved to make certain the integrity of the weld joint. In addition, running a finger or a fingernail along the weld joint can sometimes reveal undercut, as the surface area may really feel unequal or have a dip where the undercut exists.

Making use of correct welding methods and keeping control over vital welding specifications are vital methods for welders intending to protect against undercut in their weld joints.In verdict, identifying, avoiding, and repairing undercut welding problems in your welding projects is vital for ensuring durable and solid welds. By comprehending the common reasons of undercut, being able to determine it in welds, executing preventive actions, and utilizing correct techniques for dealing with undercut, you can avoid possible issues important site and produce top quality welds.

Report this page